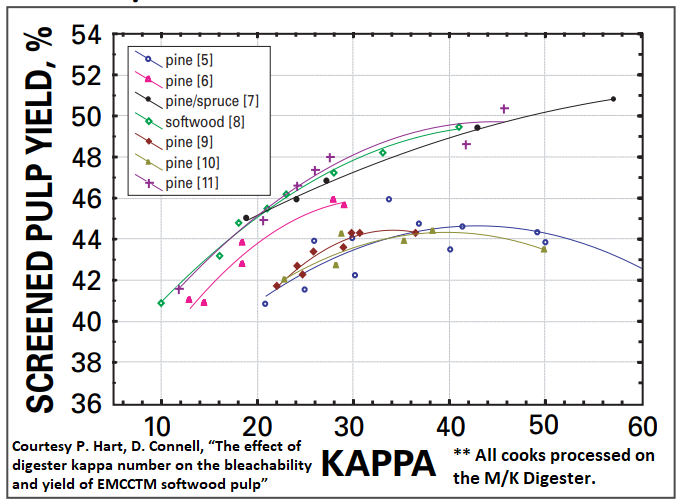

Increase your pulp yield

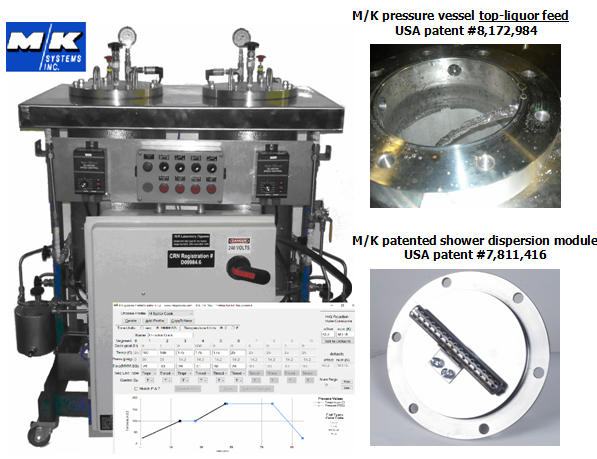

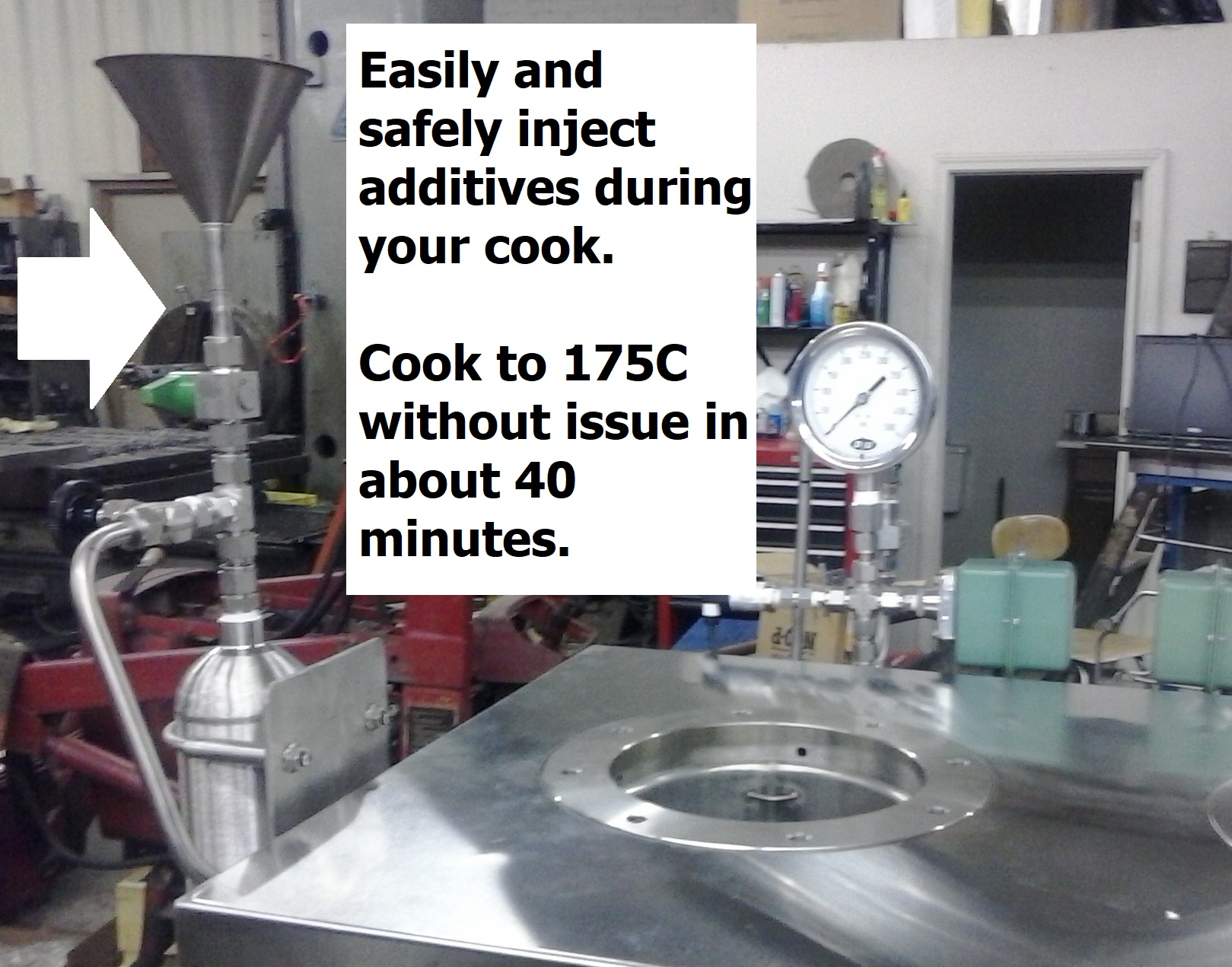

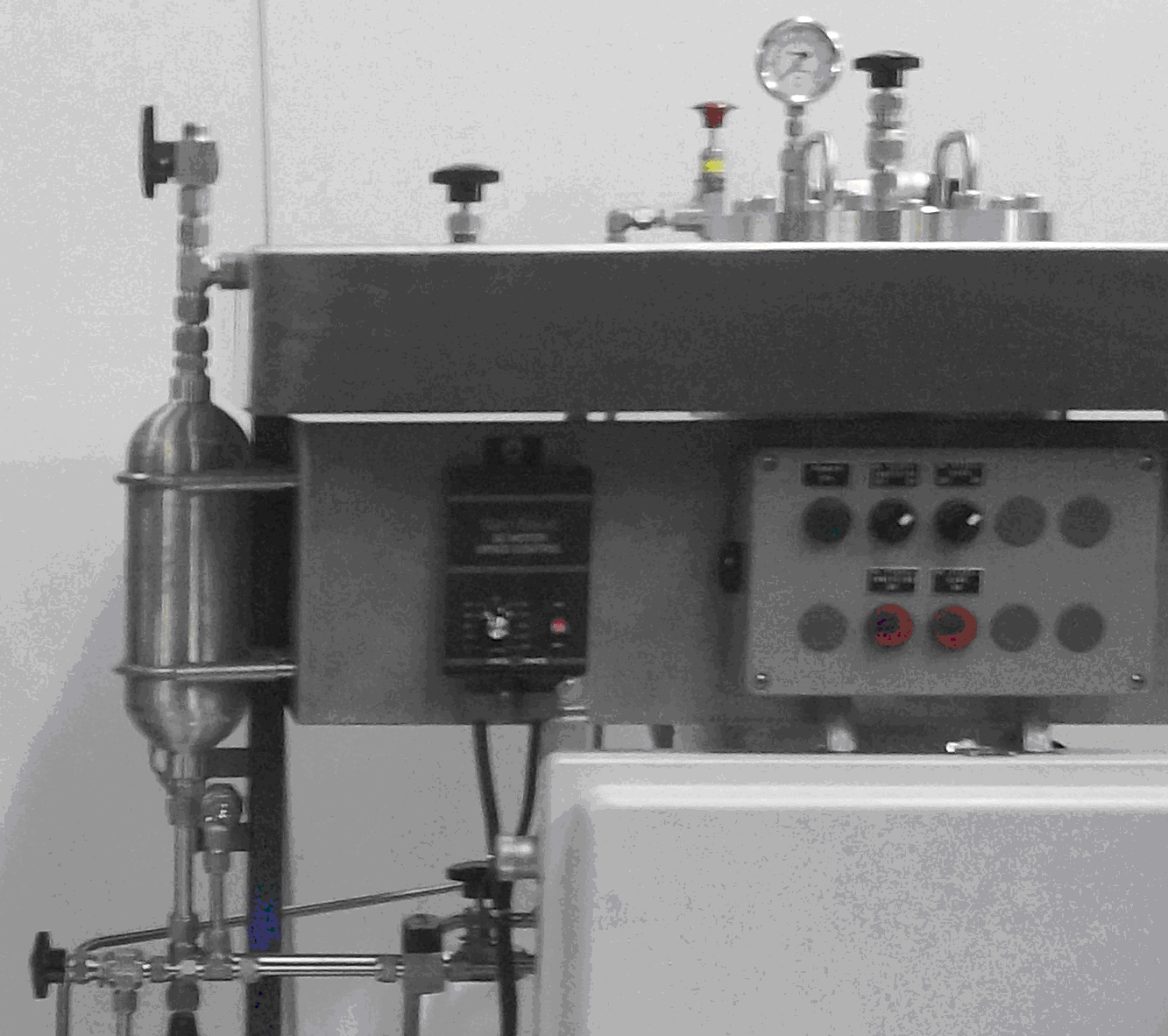

M/K Systems Inc. offers the most precise laboratory pulp digesters available. Our liquor circulating pulp system uses an anti-turbulent design, patented shower head design, stainless steel vessels and tubing, and a multi-heater system to uniformly cook your pulp. This laboratory pulp digester is ideal for Kraft cooks, hemicellulose cooks, or any type of cellulose product (including fine particle materials). Cook in 1 vessel, 2 vessels, or our multi-vessel systems. Transfer liquor between vessels. Our patented mixing module provides the best liquor/chip interaction available. Heat by temperature/time segments or by H-factor. Obtain low variation in your KAPPA numbers. Extract liquor during the cook with our enhanced sampling condenser design. Cook wood chips, hemp, fine particles, or almost any cellulose-based material. We have options that allow you to easily and safely inject additives during your cook. Rent or purchase our high-pressure pulp digesters for all of your cooking needs. The digester is easy to use, safe, and reliable. Use our systems for kraft cooks, sulfite cooks, bleaching, extraction of hemicellulose, cooking with additives, process bagasse, etc.

M/K Systems is the only company that circulates the liquor over six individual vessels. The M/K Systems circulating method offers key advantages over competitors. This is highly advantageous.,

1) Better Mixing, Better Cooks, Better repeatability: The M/K Systems Digester offers better liquor/cellulose mixing compared to competitors. The M/K Systems digester, employing a patented shower head spraying nozzles, allows the customer to rapidly flow fluids through the substrate. No competitor system can match this deep fluid penetration into the substrates. Better mixing means better, more repeatable and reliable results.

2) More realistic to larger scale systems: The M/K Systems method of flowing liquor offers a more realistic approach to larger production.

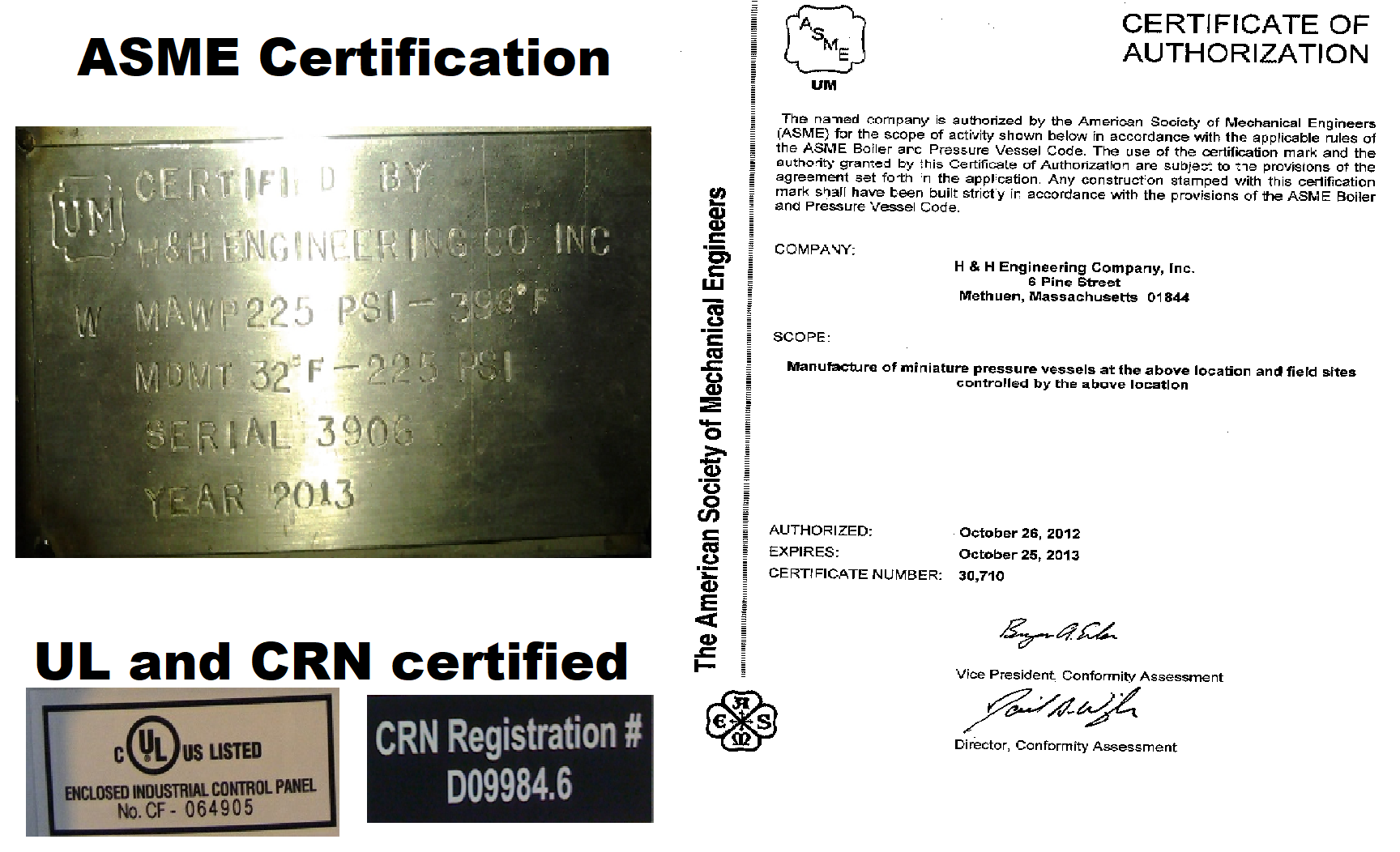

3) More accurate heating system The M/K Systems multi-heater digester uses rapid cooking methods including a jacketed-heater wrapped around the vessel as well as the inline heater. This results in greater temperature precision compared to any competitor device.

4) M/K Systems is the only company that offers a circulating digester system that records both liquor and vapor temperatures. This allows the user to understand when equilibrium is reached, as well as more thorough understanding of the cooking solutions and vapors.

5) M/K Systems is the only company to use our patented shower-dispersion nozzle. This results in the best liquor/cellulose interactions.

6) M/K Systems uses patented efficient digester vessels: Our patented top-liquor-feed (patented) vessels are the most efficient in the industry. Since most of the heating is used to heat the 316 stainless steel vessels, it is vital to make use of the vessel spacing. Inefficient vessels result in the user heating empty space, unlike the M/K Systems patented digester.

7) M/K Systems is the only company to employ resistance-designed vessel jacket heaters and inline heaters, thereby avoiding excessive inline heater temperatures that can damage the liquor. This is a significant advantage over earlier M/K Systems digesters models.

M/K Systems has 2 current technology patents used in the design (US Patent 8172984 and US Patent 7811416).

-

See what M/K Systems customers say about us:

"We have equipment from MK Systems for over 25 years. The 6-liter digesters have recently been upgraded and we have acquired new 20-liter digesters. The collaboration with the people at M/K Systems is excellent. When we have questions, we get the answers quickly. Discussions with the people at M/K Systems are very beneficial to our work. Being a research center, we work with several unconventional raw materials and their advice allows us to move our projects forward more quickly. Also, when we need spare parts, these are delivered very quickly.” -Dr. S. Duquette

Some of the typical cooking materials include:

All Soft Woods & Hard Woods

Bamboo

Bagasse

Bio-based materials

Contact Us

Get in touch with us today for more details! Our personnel will be glad to answer your inquiries.