The M/K 3D Formation Tester model 1200: The most accurate optical formation Tester available.

Scan 320cm2 in a single test -- note that camera tests scan approximately 5cm2 per test.

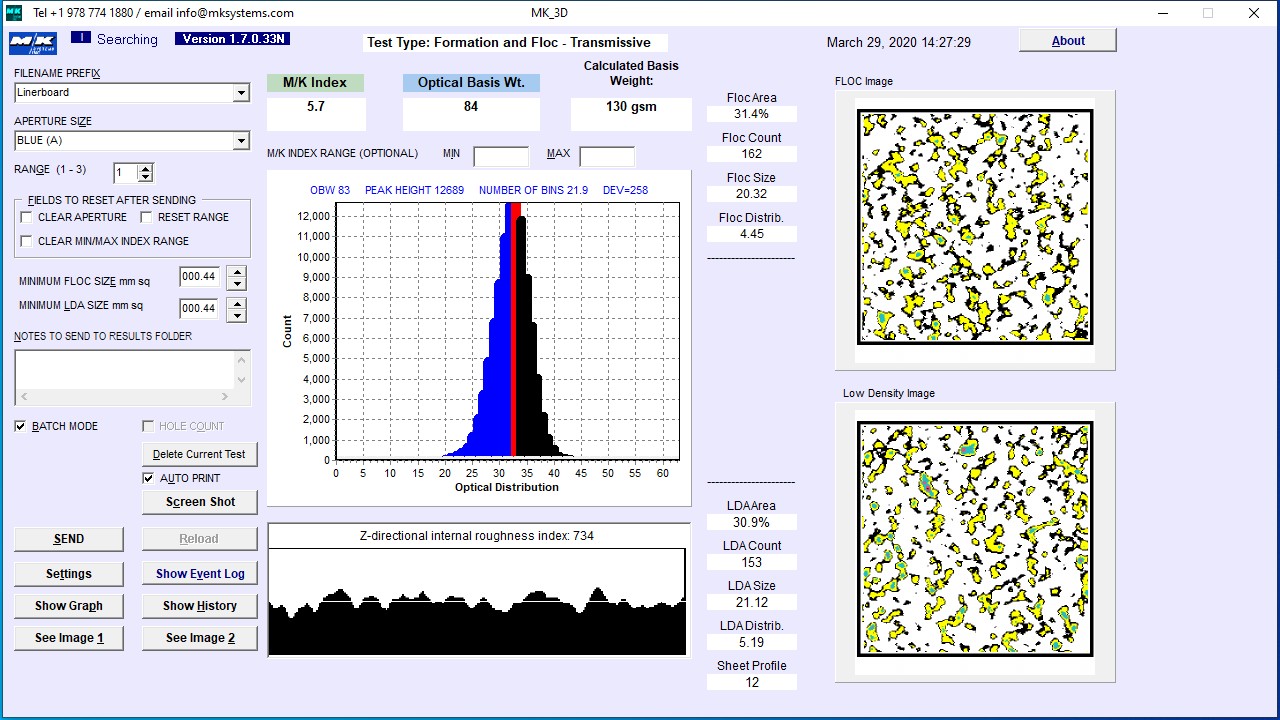

The M/K 3D Formation Tester measures the formation in paper, fiberglass, containerboard, tissues and towels, and a host of other sheet materials. In addition to measuring the formation index, the M/K also accurately measures the defects and flocs inside the sheet, as well as low density pockets, basis weight, and internal standard deviation. Unlike camera systems, our device uses a laser-type focused beam of light to accurately measure the optical density each pixel of the sheet. Test all grades of paper: bond, liner board, recycled, copy paper, coated papers, colored papers, or any other grade. In a single test, the M/K formation tester scans a large 320cm2 area (16cm x 20cm), with each pixel measured independently. No other bench top formation tester can match this area of scanning, as camera systems a limited to approximately 1"x1" area scans with light-reflection issues. The M/K Formation Analyzer uses an independent pixel scanning method that avoids light scattering issues which occur in all camera systems. We also include a unique feature that allows user to change the optical sensitivity from a low setting to an ultra high setting, allowing you to filter out the less significant flocs and sheet defects. In addition to transmission analysis, we offer an optional surface scanning set of optics that can characterize the surface of your sheet. Compare wire side Vs. felt side easily and reliably.

We have doubled the resolution of our scanning with our latest "high resolution" technology. The high resolution now scans with unmatched resolution, including up to 128 different sizes of flocs.

Some industry patent references include:

1. Xerox Corporation, # US Patent #5,935,689, “Printing Method”.

2. Proctor and Gamble, US Patent #6,114,471, “Strengthening paper”.

3. Kimberly Clark, US Patent# US 7,258,758, “Strengthening nonwovens”.

4. Rayonier, US Patent#8,497,410 “Method for making absorbent products”.

5. Newpage, US Patent #8,727,528, “Glossy recording medium for inkjet printing”.

Copyright © M/K Systems 1969-2022